For a medical device business scaling up from Startup to medium-size, it’s critical to establish a culture of quality at the onset. If sufficient time and effort are not invested early on, during the development stages, QA will be perceived as a hinderance to development and the cost to implement quality will be higher. Early planning and implementation of QA processes is required not only for compliance but also for good business.

“Let’s plan quality!”

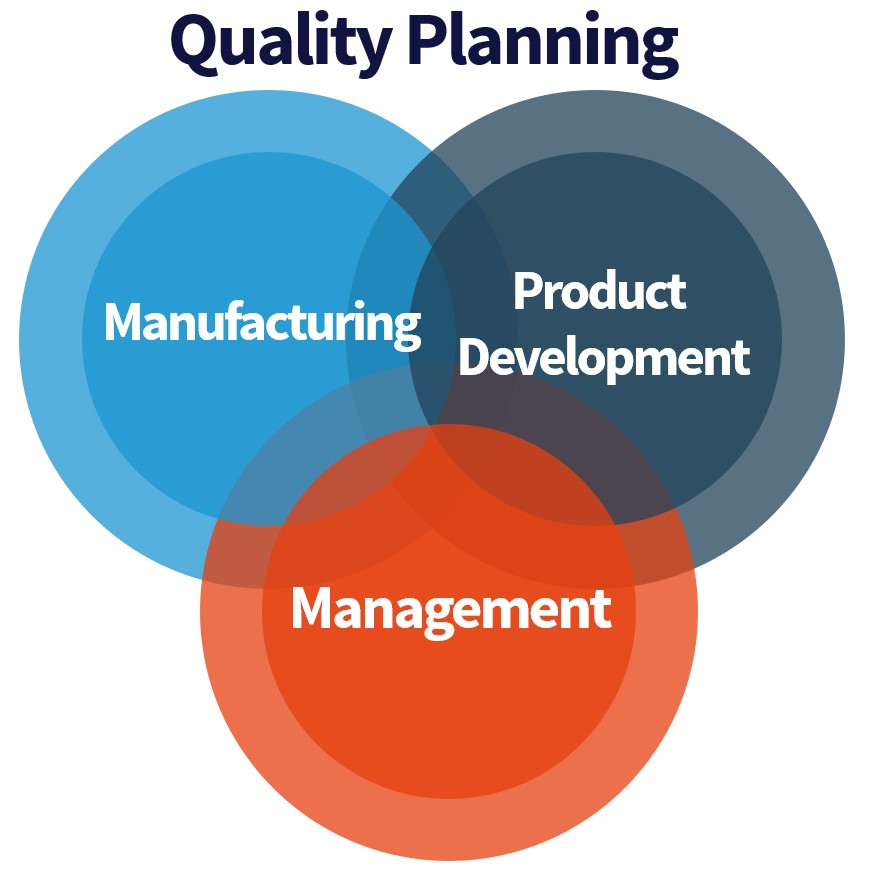

There is often confusion regarding the scope of a quality plan. Some quality plans consist of manufacturing flow charts, Device Master Records, or product development tasks. Maybe the confusion lies in the scope of (total) quality planning involving different teams and departments. Also, different quality tasks need to be planned at different times – not to mention the challenges of planning and implementing quality for projects and operations. It becomes clear that quality planning is not one endeavor resulting in one document.

Taking a step back to analyze ISO 13485 and FDA 21 CFR 820, and concerning quality planning:

Quality Management System

ISO 13485:2016 §5.4.2 Quality Management System Planning states that top management shall ensure that the QMS is planned to meet the requirements as per the standard and as per the quality objectives.

21 CFR 820.20 (d) States that each manufacturer shall establish a quality plan which defines the quality system (practices, resources, and activities), and the manufacturer shall establish the QMS (how the requirements for quality will be met)

Design and development / Design Controls

ISO 13485:2016 § 7.1 Planning of Product Realization applies to everything needed to realize a deliverable including design, production, installation, servicing, etc. § 7.1 states that all these activities, including risk management, need to be planned to meet quality objectives and product requirements.

ISO 13485:2016 § 7.3.2 Design and Development Planning. Although the term “quality plan” is not specifically written, the design and development plan is a quality plan as it specifies how the product design requirements will be achieved.

21CFR 820.30 (b) Design and Development Planning. Same as above.

Production and Service Provision / Process Control

ISO 13485:2016 §7.5.1 Production and service provision shall be planned carried out, monitored and controlled to ensure that product conforms to specifications

CFR 820.70 Production and process controls. Each manufacturer shall develop, conduct, control, and monitor production processes to ensure that a device conforms to its specifications.

Although there is some overlap in the 3 quality groups specified above, they are managed and controlled by different teams and at different periods during a product lifecycle. It may make sense to have 3 quality plans. Having 3 plans provides better clarity on the role of quality in different groups, and allowing teams to focus on their core competencies:

QMS Plan details the design, implementation, and maintenance of the QMS. The MDSAP Audit Approach (MDSAP AU P0002.005) states that the plan should at least specify the inputs and outputs of the QMS planning process.

If top management starts early and applies serious effort to the QMS planning process, the organization will develop a culture of quality. Linking quality objectives to corporate goals is an effective way to achieve this since team and personal performance is often linked to corporate goals. It shouldn’t be too difficult to track down processes that are related to achieving business goals, and establishing key metrics to improve those processes.

Product Development QP. Details on how quality is to be implemented in the development of the device should be included in the product development plan. SOPs should be referenced, and any deviations or exceptions should also be justified. For example, if the device being developed is a product line extension or a part of a family of products, some QMS processes may be leveraged against other products of the same family. In all cases, the QP section of the product development plan should map out how to achieve:

- Product design requirements

- Quality objectives, quality metrics (for the development phases)

- Completed technical file

- Transfer to production

A QA specialist should be part of the development team, and their main role is to train and advise the other members, not police the development. The QA specialist should also keep the team updated on any new or revised standards and regulatory guidelines. The project manager of a medical device development project should be an expert in QA since almost all tasks are controlled by a quality process (SOP). The success of the product development project relies on 1) delivering a high-quality technical file for regulatory approval, and 2) delivering high-quality production specification. Due to high cost and timelines of medical device projects, it is worth doing the right thing the first time.

Manufacturing (or Production) QP. Production and service provision shall be planned, carried out, monitored and controlled to ensure the final product conforms to specifications. It should be one document which lists or references:

- Processes required to produce and deliver the device (including packaging, labeling, sterilization, storage, installation, and servicing)

- For each process: Infrastructure & Environment, Personnel, suppliers, equipment, tools, instruments

- Input and output to each process (Ex. Input: raw materials/subassembly, Output: subassembly)

- All controls (trainings, inspections, qualifications, verification, equipment monitoring & measurement) for:

- Input to process

- Process: personnel, suppliers, equipment, tools, instruments

- Output to process

Separate quality plans as described above give a better opportunity to integrate quality throughout the organization. This strategy also makes the roles of quality clearer to all groups in the organization.